Pre-prototyping unit

The pre-prototyping acts as an interface between upstream research and transfer centers (CEA, INERIS, IFPen). Its objective is the integration of new electroactive materials in demonstrators (battery prototypes, supercapacitors, etc.) which are reliable and reproducible, in order to assess and demonstrate their applicative potential.

Our equipment helps to assembly batteries whose capacity is of the order of 1 to 2Ah and to validate the pre-transfer of materials from the network or from industry (electrode materials, salts and solvents). Our team works in close collaboration with the transverse theme “Security”.

The pre-prototyping unit gathers 4 units that allow a quick transfer from a concept to the validation at the level of a demonstrators (prototypes). The objective is to validate the preliminary results on applications on a pre-industrial scale, by producing prototypes of accumulators in the 18650 format commonly used in industry.

- The Upscale of Materials unit, the objective of which is the synthesis of active materials used in the accumulator prototypes; from 1g to 500g. The aim is to find synthesis routes easily transferable to industry.

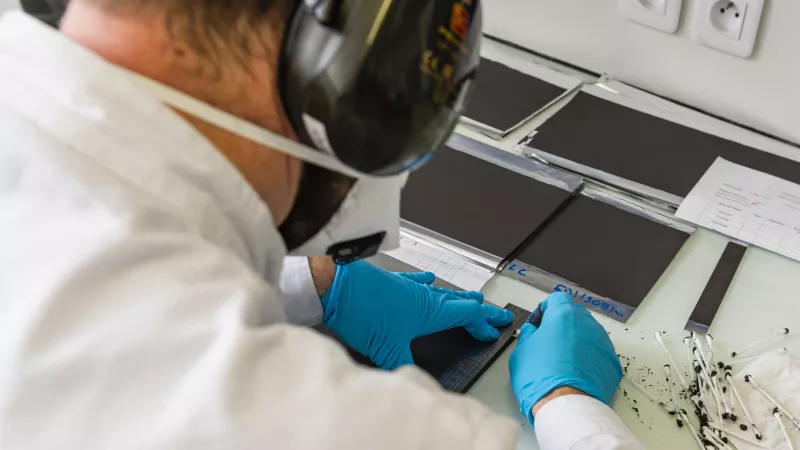

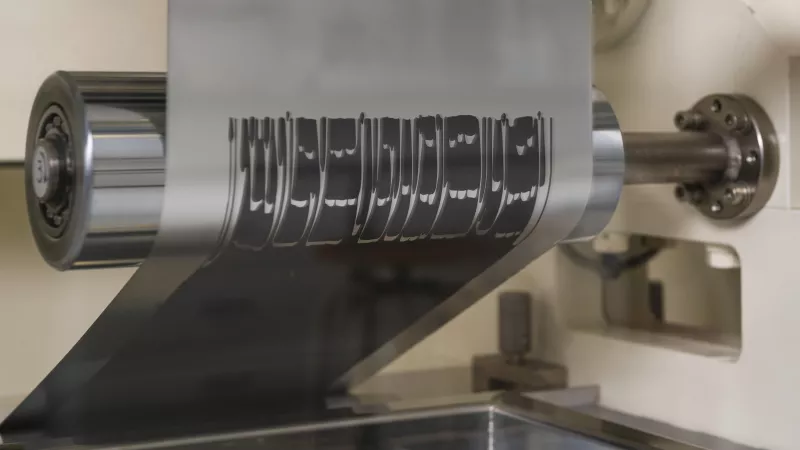

- The electrode manufacturing unit, which includes formulation, calendering, cutting and winding,

- The prototyping platform where are produced and assembled the 18650 accumulators,

- The characterization unit, where tests are carried out on the finished prototyped: electrochemical tests, power and energy measurements, aging, self-discharge and post-mortem analysis.

Beyond the technological preoccupations, we try to fundamentally and quantitatively understand the links between the properties of electroactive materials (texture, surface chemistry…), the composition of their electrodes (formulation including non-electroactive additives), their shaping process and its parameters, the architecture of these electrodes, their electrical and mechanical properties at their different scales, the basis weight and porosity of the electrodes, and their electrochemical performance.

The platform’s activity also includes research and evaluation of new formulations and new non-electroactive additives, the development of new manufacturing processes and the research of new electrode and device architectures.

To do this work, we develop skills and tools for a better understanding of the behavior of inks and colloidal suspensions, such as rheology coupled with other techniques (dielectric spectroscopy, microscopy, etc.) and numerical simulation (simulation of Brownian dynamics, etc.) in relation to the “Theory” team.

The development of these tools is essential to the activities of the platform and to support the transfer on a pilot or semi-industrial scale of electrode formulations.

Au-delà des préoccupations technologiques, nous recherchons la compréhension fondamentale et quantitative des relations entre les propriétés des matériaux électroactifs (texture, chimie de surface…), la composition de leurs électrodes (formulation incluant les additifs non-électroactifs), leur procédé de mise en forme et ses paramètres, l’architecture de ces électrodes, leurs propriétés électriques et mécaniques à leurs différentes échelles, le grammage et la porosité des électrodes, et enfin leurs performances électrochimiques. Sur cette base scientifique, l’activité de la plateforme comprend également la recherche et l’évaluation de nouvelles formulations et nouveaux additifs non-électroactifs, le développement de nouveaux procédés de fabrication, la recherche de nouvelles architectures d’électrode et de dispositif.

Ce travail passe notamment par le développement de compétences et d’outils pour une meilleure compréhension du comportement des encres et des suspensions colloïdales, tels que la rhéologie couplée à d’autres techniques (spectroscopie diélectrique, microscopie, etc.) et la simulation numérique (simulation de dynamique brownienne, etc.) en relation avec la thématique théorie. Le développement de ces outils est essentiel à l’activité de la plateforme, mais également pour accompagner le transfert à l’échelle pilote ou semi-industrielle des formulations d’électrode que ce soit sur la plateforme STEEVE du CEA ou pour un autre industriel du réseau.