How to monitor stress in batteries?

Rechargeable lithium-ion batteries (LIBs) are THE technology of the 21st century. Their excellent performance in various applications makes them essential in a broad range of strategic industries; however, there are still improvements to make in terms of energy density, power rate, lifespan, safety, and environmental footprint. The understanding of the relationship between chemo-mechanical effects and battery performance is becoming crucial, especially for all-solid-state batteries (ASSB’s) where the stress is transmitted through the device and no longer buffered as by liquid electrolytes.

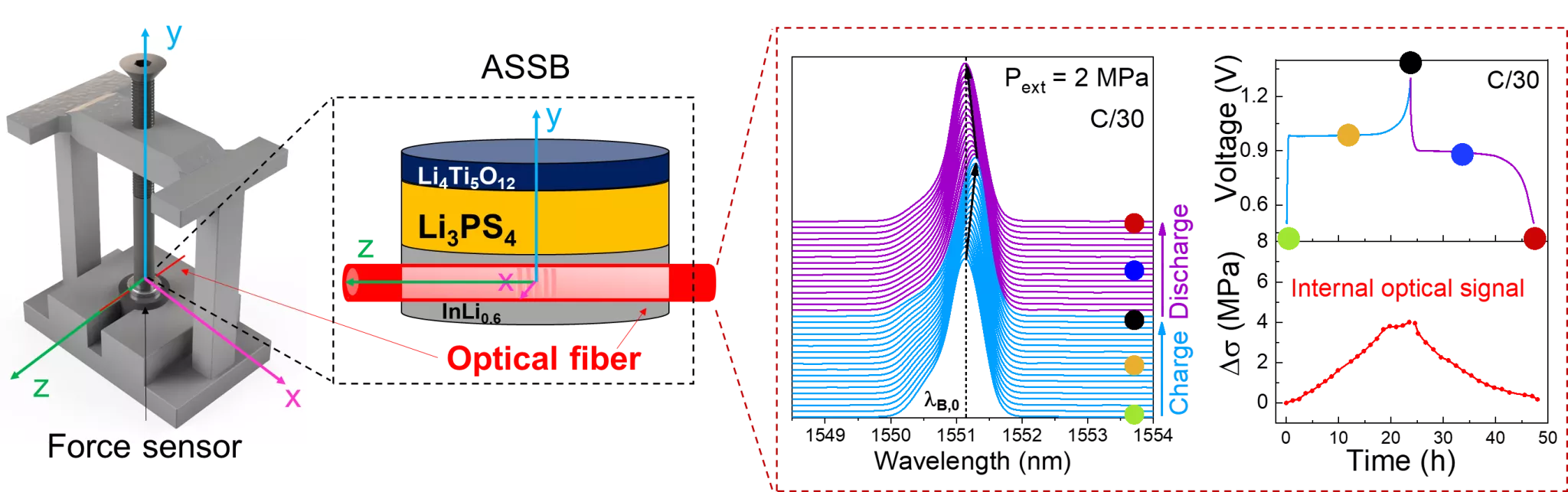

Inspired by the use of integrated optical fibers with Fiber Bragg Grating (FBG) sensors into large composite structures (such as bridges, railways and aircrafts) for health structural monitoring, Laura Albero et al. extended this approach from civil engineering to the battery field in a recent paper published in Nature Communications. By using FBG sensors, they performed operando monitoring of internal Li-driven stress changes in batteries containing either liquid or solid electrolytes.

First, they focused on cells with liquid electrolytes using Silicon as the electrode of study, whose volume is increasing up to 280% when fully lithiated. Their results show that FBG sensors can track the lithiation mechanism in electrodes containing either micro-Si or nano-Si electrodes, highlighting their differences and revealing the importance of the porosity in buffering the volume changes at the electrode level.

In the second part, the authors explored the implementation of this new technique to all-solid-state batteries. Indeed, by monitoring the variation of the optical wavelength signal (ΔλB) during cycling, and converting it into stress variations (Δσ) the researchers could access quantitatively to Li-driven local stresses at the electrode level, which has never been achieved so far in ASSB’s with external force sensors.

On the figure: Scheme of the modified coin cell with the implemented optical fiber and the external force sensor in a InLix | LPS | LTO cell with the FBG sensor embedded in the anode. The results show the operando Li-driven stress monitoring during a galvanostatic cycle at C/30. For all the recorded spectra, a single Bragg wavelength peak is seen, whose maximum (λB) progressively shifts to the right towards higher values upon charge (light blue curves) and shifts back to the left upon discharge (purple curves), thus revealing the high mechanical reversibility of the system.

Finally, to prove the added value of this approach, the researchers evaluated internally the stress occurring at the electrode level in symmetric all-solid-state cells where external force sensors were totally blind to monitor any stress variation, hence highlighting the benefits offered by internal rather than external stress monitoring in solid-state batteries.

In summary, the results presented in this work are aiming to provide a new characterization tool to explain failure phenomenon in batteries meanwhile bridging scientists and engineers from multidisciplinary fields to facilitate the development of new electrode and battery designs.

The study and its conclusions can be found in detail here.

Laura Albero Blanquer is currently a PhD Student from the CSE in Collège de France under the supervision of Jean-Marie Tarascon. After a bachelor in Nanoscience and Nanotechnology at Universitat Autònoma de Barcelona (UAB), Laura got curious about nanomaterials for Energy Storage applications. This is why she joined the MESC master program, where she had the opportunity to study in Toulouse, Warsaw, Amiens, and Gothenburg. At last, she performed her Master Thesis in Gothenburg, at Chalmers University of Technology, under the supervision of Prof. Patrik Johansson and in collaboration with the company Insplorion AB.

Her PhD thesis on optical sensing in batteries allows her to focus on the development of sensing techniques using commercial Fiber Bragg Grating (FBG) sensors. Thus, she aims for the operando monitoring of physical parameters such as temperature, hydraulic pressure, and stress, which are essential for improving the battery performance. Currently fully focused on writing her PhD thesis, Laura has not yet decided whether her future will be in academia or industry. However, through this thesis, she has enjoyed doing fundamental research on concrete technological problems.

After such a promising proof-of-concept to use FBG sensors as a new operando tool for monitoring the stress evolution, the next challenge is to implement it to practical problems in batteries such as studying layered cathodes in all-solid-state batteries. Moreover, given the feasibility to use the FBG sensors to perform optical calorimetry in 18650 Na-ion cells that was reported in 2020, another project currently running aims to generalize this approach to other cell configurations and cell chemistries such as Li-ion pouch cells, targeting commercial batteries.

Although not funded by RS2E, Laura had the opportunity to present her work within RS2E and exchange scientific data with industrial and academic partners in the network. This is why she described this experience as "rich and instructive". To her credit, Laura has authored or co-authored five papers mainly in the area of battery sensing and monitoring and has also collaborated on topics such as all-solid batteries and self-repair. Finally, two other manuscripts related to her PhD work are in preparation.